Outline

1. The Smoke Kit for Engines (HO)

2. The Pump Kit (All Sclaes)

3. The Smoke Kit for Structures (All Scales)

KIT Instructions: (Please Copy for your records)

|

The Smoke Kit for Engines, HO (Can

be applied for all Scales)

|

THE SMOKE KIT

PARTS LIST

For All, HO

Scale Engines.

1. Seuthe Smoke Element

2. Split Ring (To hold Seuthe Element to Metal Stack)

3. Metal Smoke Stack (negative electrical connection -)

4. Insulator (Insulate between Positive and Negative charges)

5. Contact spring (Contact for bottom of Seuthe Element)

6. #24 gauge wire (positive Electrical connection +)

Basic Instructions:

ASSEMBLY

INSTRUCTIONS FOR YOUR

"SMOKE Kit

for Engines"

BACKGROUND

FACTS ABOUT YOUR "SMOKE KIT for

Engines"

This kit will add

to the realism of putting "Smoke in your stack right on the track"

once installed into your Engine. This kit is very versatile and can be added to

a chimneystack to produce smoke for a factory or other manufacturing plants with

MNP's PUMP KIT.

This kit contains

all the necessary parts, which can be modified to fit into all types of Engines

or structures. The kit is Primarily for HO

Scale Engines but can be used for all

scales in model railroading. Obviously, this is not a stand-alone kit. Once

you decide to install this kit into your Engine or structure, please follow the

instructions in READ THIS FIRST for the steps needed for installation.

IMPORTANT

-- READ THIS ENTIRE PAGE FIRST !!!

1. Before beginning

to assemble your Smoke kit read all the instructions, tips through once, and

familiarizes yourself with all the parts and their proper location by comparing

them to the drawings. All parts are numbered to corresponding picture on the

Back.

2. Decide the

structure or Engine in which to install the Smoke kit and the EXACT location of

the ENGINE or structure. Once the

Smoke kit is installed, it is very difficult to move or install into another

Engine. If you are a HO scale model

railroader, sample instructions will be illustrated in the assembly

instructions, but if not the instructions can still be applied to any

application so do not worry.

3.

SEE THE BACK OF THE COVER PAGE FOR THE PARTS LAYOUT!

____________________________________________________________________________________________________________

TIPS:

Smoke

Stack:

1.

Measure the OUTSIDE Diameter (0.2490" or 1/4" Dia.) of

the Metal smokestack. When Drilling a Hole make sure that the Metal is a tight

fit. This will be the (negative -) ground for the Smoke element.

2.

Remove all the Burrs on the Metal smokestack.

3.

Measure the total Length of the metal smoke Stack (1.16")

Spring/wire:

1.

Solder the Wire (RED, positive) to one end of the spring.

2.

Make sure the spring fits into the insulator. (IT MUST NOT TOUCH

THE OUTSIDE OF THE INSULATOR) and the wire travels through the insulator.

3.

On the otherside of the Spring Bend the TOP COIL only to close the

gap, to ensure Better Contact with the bottom of the Seuthe Element.

Insulator

Check:

1.

File or trim the OUSIDE of the insulator so that it is a very

tight fit into the smokestack. DONOT PUSH the Insulator into the smokestack at

this time.

2.

The insulator must be tight so that it will not move when

installed into the smokestack.

Slip

Ring:

1.

Place the Slip Ring onto the Seuthe Smoke Element.

2.

Gently place it into the smokestack.

3.

FROM THE BOTTOM Side of the smokestack, measure the distance to

the bottom to the Seuthe Smoke Element.

4.

This is where the spring and the Insulator must be to make contact

to the Bottom of the Seuthe Element.

Insulator

Installation:

1.

Once you determine the exact position of the insulator, push it

into the smokestack.

2.

Now, install the spring and wire into the insulator.

3.

Gently push the Slip Ring and Seuthe Element into the smokestack.

(PLEASE TEST USING THE RED AS POSITIVE +, AND THE OUTSIDE OF THE SMOKE

STACK AS NEGATIVE -) (PLACE A FEW DROPS ONTO THE ELEMET, SO IT WILL NOT BURN

OUT!!!)

CAUTION:

THE ELEMENT WILL GET VERY HOT!!!!!!!!

Once you have

tested the Smoke Element, you are NOW READY to install it into your Engine.

Unfortunately, we at MNP Do NOT have all instructions for all Engines. This will

be up to you! However, Feel Free to CALL US!

General

Tips:

1.

The Metal Stack Must be grounded (Negative -) Always. The Stack

must fit tight into the Hole you Drill.

2.

Run the wire (Red, + Positive) to the positive lead in your Engine

or Structure.

3.

Plan each step Carefully, take your TIME!

CALL

for Technical Assistance or spare parts, We will be glad to HELP

à

à

1-757-596-2309

Thank

you for purchasing this fine kit, and look for other kits soon!!!!

|

The Pump Kit for All Scales

|

ASSEMBLY

INSTRUCTIONS FOR YOUR

"LIQUID

SMOKE, PUMP KIT"

BACKGROUND

FACTS ABOUT YOUR "LIQUID SMOKE,

PUMP KIT"

This

kit will add to the realism of putting

"Smoke in your stack right on the track" once installed into a water

tower, or water pipe, on your layout. This kit is very versatile and can also be

added to a chimney stack to produce smoke for a factory or other manufacturing

plants with MNP's SMOKE KIT.

This

kit contains all the necessary parts which can be modified to fit into all types

of structures. The kit is for all

scales in model railroading. Obviously, this is not a stand alone kit. Once

you decide to install this kit into a structure, please follow the instructions

in READ THIS FIRST for the steps needed for installation.

IMPORTANT

-- READ THIS FIRST

1.

Before beginning to assemble your pump kit read all the instructions and tips

through once and familiarize yourself with all the parts and their proper

location by comparing them to the drawings. All parts are numbered to

corresponding picture on page 2.

2.

Decide the structure in which to install the pump kit and the location of the

structure on your railroad layout. Once the pump kit is installed it is very

difficult to move or install into another structure.

If you are a HO scale model

railroader, sample instructions will be illustrated in the assembly

instructions, but if not the instructions can still be applied to any

application so don't worry.

3.

Decide the location of your

reservoir, be sure to install it in a location easy accessible for refilling and

the shortest distance to the pump as possible. This will reduce the amount of

liquid smoke needed for maintaining the pump system.

4.

Decide the location of the push

button which you can easily see the smoke stack of

your engine and the end of the hollow metal tube to enable you to see the

actual action if installing it into a water tower which is widely used.

5.

Once you decide the location of the

main components, it will be very easy to complete the installation of this kit,

so plan ahead.

6.

The electrical pump uses 6 volts only. The kit is equipped with a battery holder for (4) C

batteries which can be mounted anywhere on the layout. An A/C and or DC

converter can be used to reduce the voltage from 12 Volts DC to 6 Volts DC if

you do not want to use the battery holder.

TIPS

1.

The most important installation is the hollow metal tube. Once the decision is

made to fit and bend the metal tube, it is very difficult to readjust the tube.

SO BE CAREFUL!!!! Once installed, the end of

the tube should be slightly higher

than any point along the tube. This will prevent dripping out of the end of

the tube.

2.

Once the pump, reservoir, battery holder, and structures are mounted, the hoses

can be easily run at the correct length. Use

the connectors as an intersection point when adjoining the hoses from the

reservoir and tube to the pump hoses.

3.

When installing the suction hose in the reservoir the end of the hose should be

slightly higher than the bottom of the reservoir. Cut the bottom of

the hose on a slight angle so it can always pick up liquid smoke.

4.

Once the pump, push button and battery holder are mounted the electrical wires

can be easily run at the correct length.

5.

When installation is complete and all hoses are connected, priming the system is

necessary to remove all air from the hoses and pump. When priming the pump

system fill the reservoir full of liquid smoke, push the button using small

intervals to allow the oil to slowly move through the system. Do

Not continuously run the pump!!!

Note:

It may take 5 minutes or so depending on the length of the hoses to

completely prime the pump system. Once the system is primed, there should be no air in the hoses and

the liquid smoke should drip out of the tube with no bubbles.

A

Completed system installed into a water tower used in HO scale.

The description and assembly for this pump system are

located on the following pages. The basic assembly and operation will be

discussed on the following page. Remember

it is up to you to decide what application this pump kit will be modified to fit

into.

The

parts are numbered by the following:

Part

no.

1. The

optional battery holder will hold 4 C batteries for independent operation, or a

converter can be used to hook up to your system. CAUTION the electrical motor can only hold 6V!!!!

2a,2b,2c.

Are the electrical wires. The wires can be run according to the diagram.

3.

The normally open electrical push button which will activate the circuit

can be wired according to the diagram. The push button should be mounted in a

line of sight to the hollow metal tube, so that when pushing the button you can

see the liquid smoke drip from the tube into the engine's smoke stack.

4.

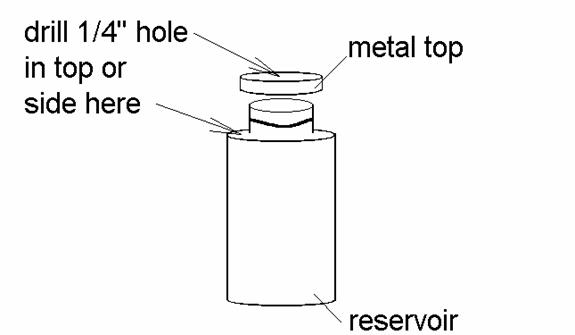

The reservoir which will store the liquid smoke. The reservoir should

be mounted in a place for easy access so refilling of

liquid smoke is easy. A 1/4 hole in the metal top must be made so that

the suction tube can be installed. The suction tube can be modified for any

suitable position on the plastic reservoir. The option is yours.(see following

diagram) IF you want to install the hose at the bottom of the reservoir you will

need to call MNP for extra fittings.

5a,5b.

Is the suction side of the pump with the large O.D. plastic tube. The

plastic tubes should be hooked up last to ensure the correct length. DO

NOT cut the hose short.

6.

The large connector will adjoin the hose from the pump and hose from

the reservoir. Make sure that the both barbed ends of the connector are

completely covered by the end of the plastic hoses. This

will ensure no leakage of liquid smoke.

7.

Is the electrical piston pump. The pump should be mounted in the away

that the shortest distances can be run by the hoses. Located on the pump is a 90

fitting, this is the pressure side of the pump. (See picture) Also, the pressure

side has the small inside diameter hose. The suction side is located with a

straight fitting and with the larger inside diameter. The pump can be wired in

either positive or negative direction when the wires are installed

8a,8b.

The pressure hoses of the

pump with are the small I.D. plastic tube. The plastic tube should be hooked up

to the hollow metal tube before adjoining it the connector.

9.

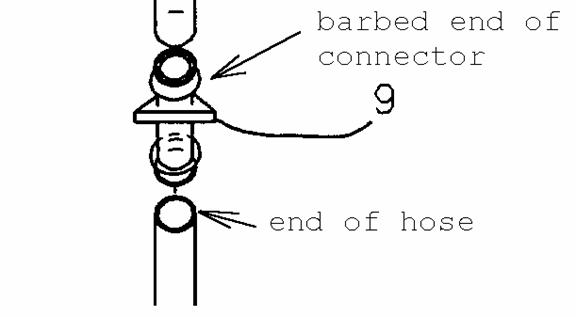

The small connector will adjoin the hose from the pump from the

hollow metal tube. The plastic tube at this end should be hooked up last to

ensure the proper length.

10. This

is the MOST IMPORTANT part in your

pump assembly!!!!! When bending the hollow metal tube take the following

precautions:

a) Install a wire inside the hollow metal tube before bending at each end

only, this will ensure that the tube will not have a

sharp pinch

point at each critical bend.

b) Decide the exact modification that the tube needs to be modified for

your application.

c) As shown below the critical bending points must be done very

carefully, so that the tube will not be damaged.

11. As

shown on page two, the pump system is installed into a water tower,

note that the hollow metal tube is installed into the spout of the

existing water tower. The hollow metal tube can be used to fit other

applications.

Other

key points:

When

installing the hoses on the barbed connectors (9),

make sure that BOTH ends of the hoses are over the barbed end for a

secure tight fit, which will ensure a leak proof system. When installing the

hose over the hollow metal tube this is only a friction fit the hose will only

be approximately 1/8" on the metal tube. (See diagram below)

When

installing the suction hose in the reservoir, you can either drill a

1/4" hole in the metal top or the top part of the plastic reservoir . It is

your option depending on the location of the reservoir. The main concern is to

have the suction hose located to pick

Up

the liquid fluid. (see diagram below).

IF

YOU NEED EXTRA FITTINGS or HOSES, PLEASE CALL: 1-757-596-2309

You

can ORDER EXTRA HOSES AND FITTINGS for other USES CALL 1-757-596-2309.

Thank

you for purchasing this fine kit, and look for other kits soon!!!!

|

The Smoke Kit for Structures

|

"THE SMOKE KIT

for Structures"

ASSEMBLY

INSTRUCTIONS FOR THE SMOKE KIT

BACKGROUND

FACTS ABOUT OUR "SMOKE

KIT"

This

kit will add to the realism of putting

"Smoke in your stack right on the track" once installed into ANY

STRUCTURE on your layout. This kit is very versatile, shown below the Smoke Kit

and (Pump kit if used together) are added to a chimney stack to produce smoke

for a factory or other manufacturing plants.

This

kit contains all the necessary parts which can be modified to fit into all

of structures. This kit is

for all

scales in model railroading. Obviously, this is not a stand alone kit.

Once you decide to install this kit into a structure, you will enjoy the ease of

operating the pump kit to install liquid smoke into your structures as shown in

the picture.

1.

Decide the structure in which to install the smoke kit and the location

of the structure on your railroad layout. If

you are a model railroader, a

sample illustration is shown below, but if not, the instructions can still be

applied to any application, so don't

worry.

USE

ONLY 12 VOLTS max.FOR WIRING THE

SMOKE ELEMENT.

A

DETAILED VIEW of The Smoke Kit and Pump Kit installed into a CHIMNEY

STACK, WHEN USED TOGETHER! THIS IS THE BEST AUTOMATIC SYSTEM FOR

PRODUCING SMOKE!

2.

When installing the smoke element into any structure, the following precautions

must be taken:

a. All bare wires must NOT

make contact with any of the plastic structures.

b. The probe on the smoke element must be exposed to the outside at the

top of any stack,

DO NOT cover the smoke element.

c. Always INSTALL the Insulator around the inside of any structure.

3.

Recommended to use MNP Design's

Liquid Smoke . When using the toggle switch, the smoke element must have

liquid smoke at all times to prevent burn-out!!

CAUTION:

WHEN NOT IN USE TURN OFF ALL ELECTRIC POWER TO THE SMOKE ELEMENT.

4.

To operate the smoke element, switch the toggle switch ON to generate the

smoke, for hours of enjoyment.

MNP IS NOT RESPONSILBE FOR ANY DAMAGES!

|

MNP QR Code

MNP QR Code